Product Introduction

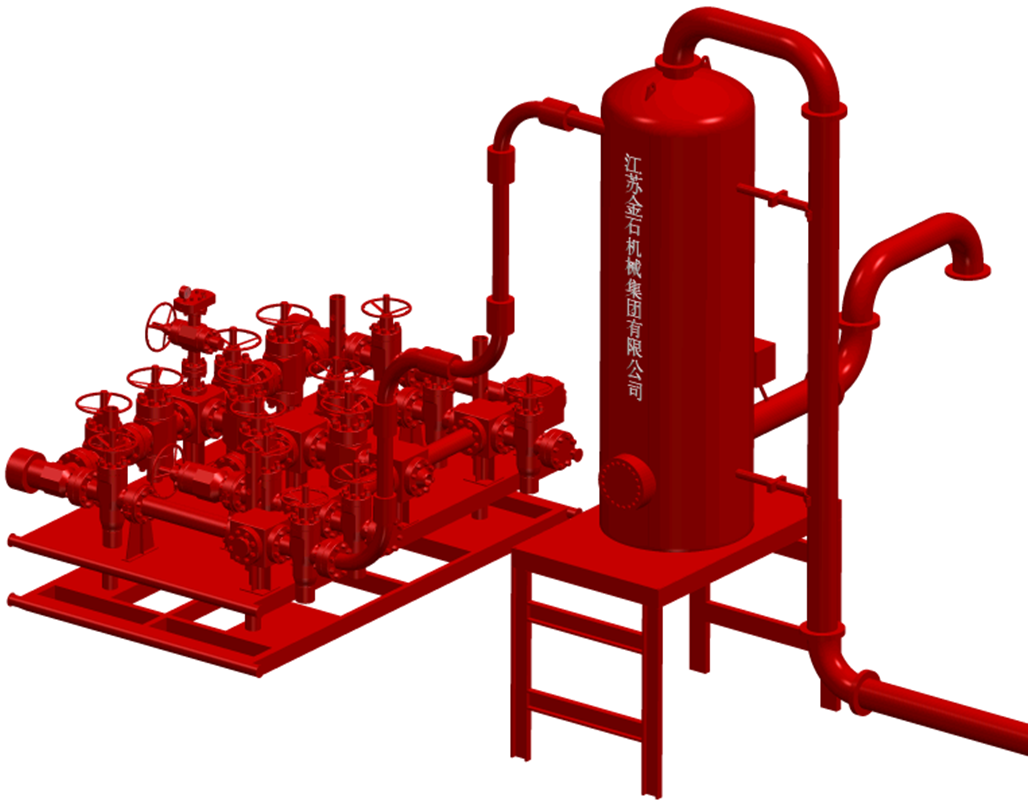

1.Throttling manifold mud gas separator

2.Underbalanced Drilling Manifold

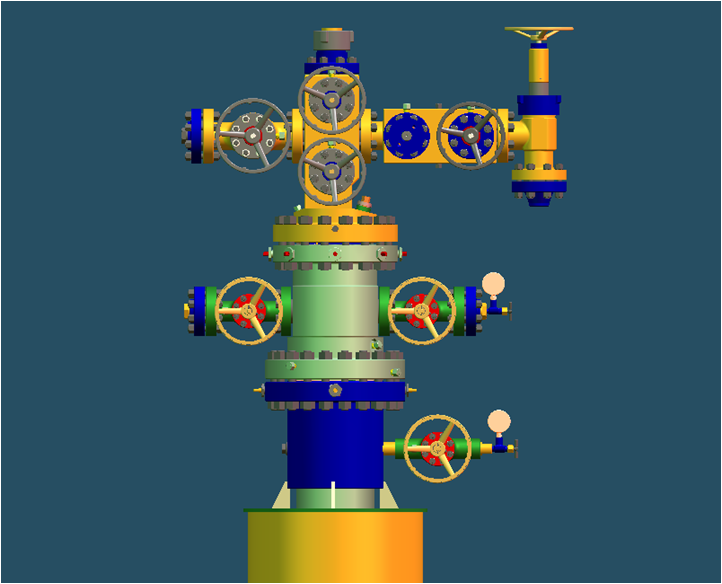

3.Choke Manifold

Executive standard: API 16C.It is the matching device for blow out preventer and it is the main equipment to control blowout and oil well pressure. Equipped with hydraulic control box, it can realize remote control.

It can be used in conjunction with mud gas separator.Safe and reliable, easy to operate.Working pressure: 2000-20000Psi.

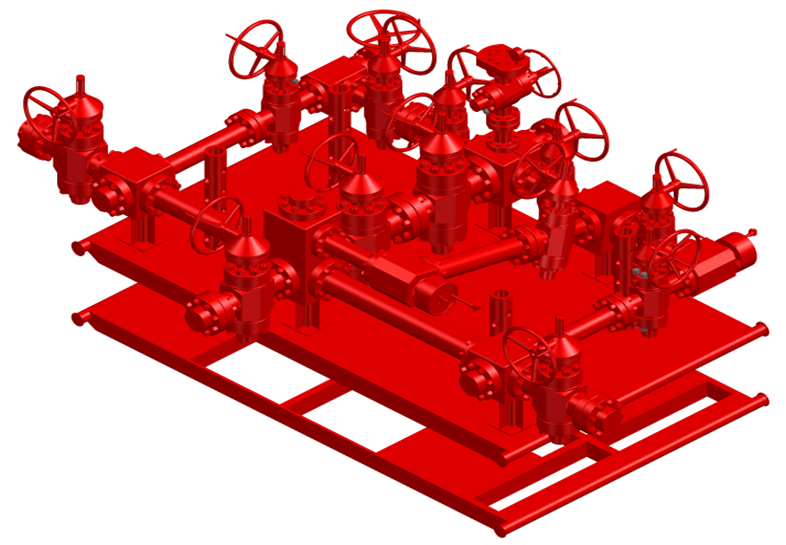

4.Kill Manifold

Executive standard:API 16C.It is used to adjust and replace mud with different density in the well to ensure new balance pressure.Equipped with hydraulic control box, it can realize remote control.It is the matching device for blow out preventer and it is the main equipment to control blowout and oil well pressure.Safe and reliable, easy to operate.Working pressure: 2000-15000Psi.

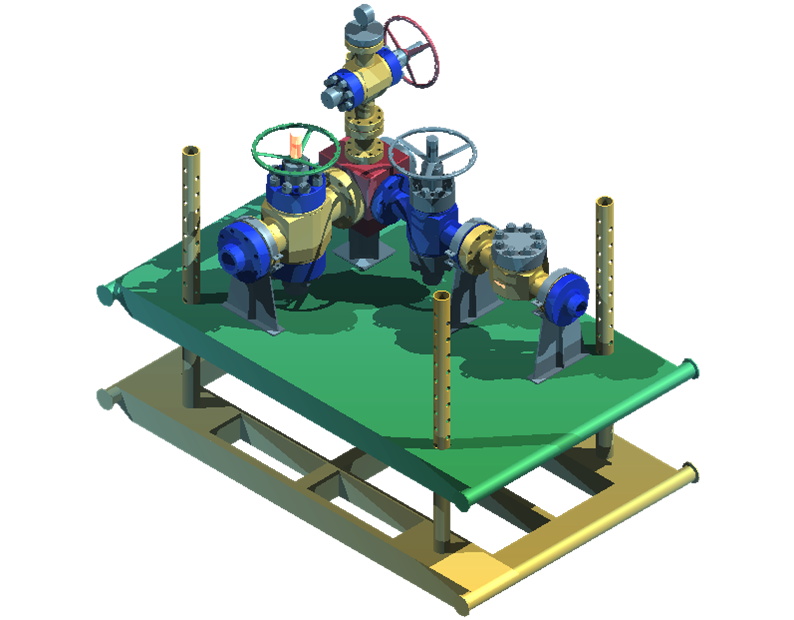

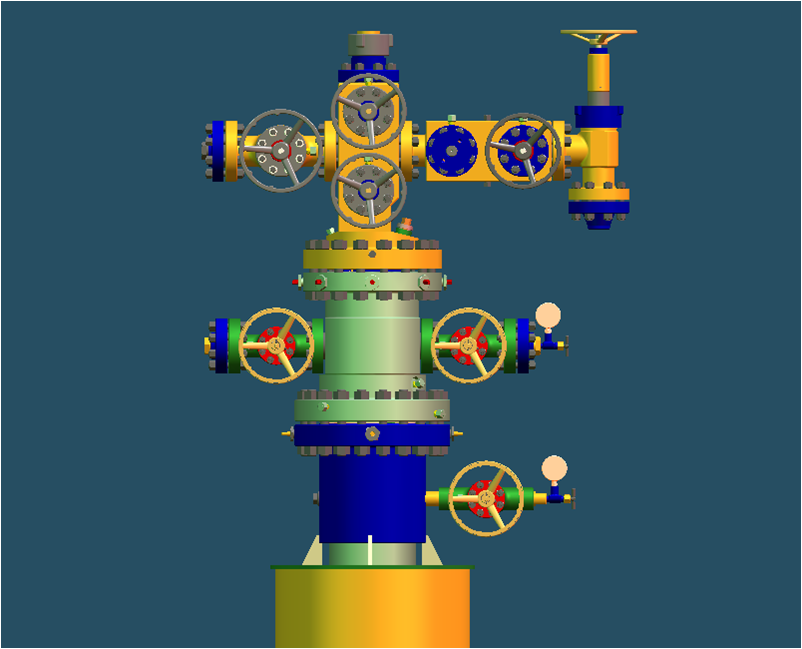

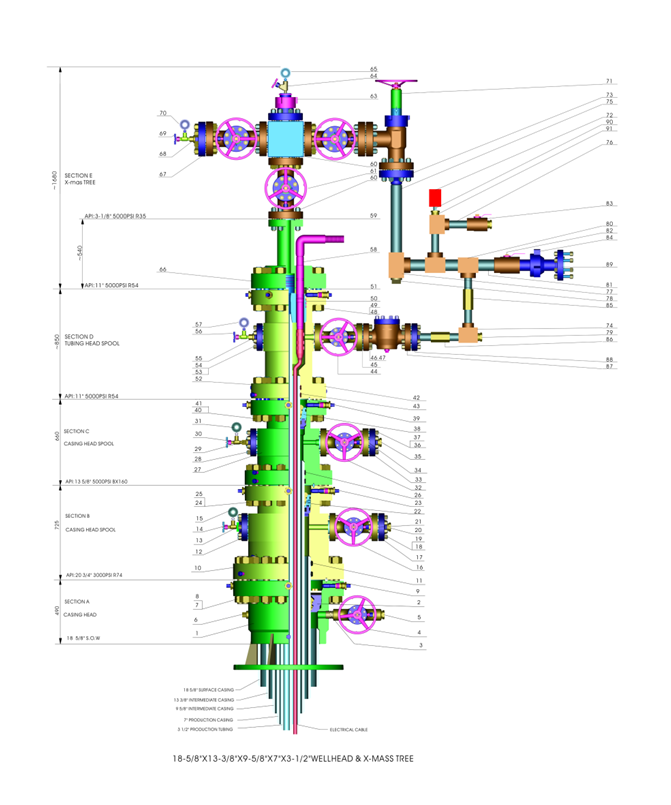

4.Electric pump wellhead device

Electric pump wellhead device directly through cable.Electric pump wellhead device with BIW connector traverser. Easy to install and Reliable seal 2000psi~5000psi direct cable crossing is often used.Low cost.

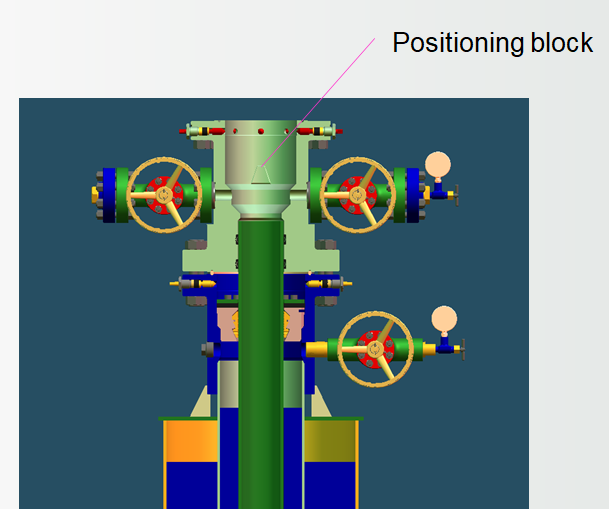

5.Tubing cross with positioning block

Tubing cross with positioning block and the tubing hanger with directional groove are convenient for field installation.

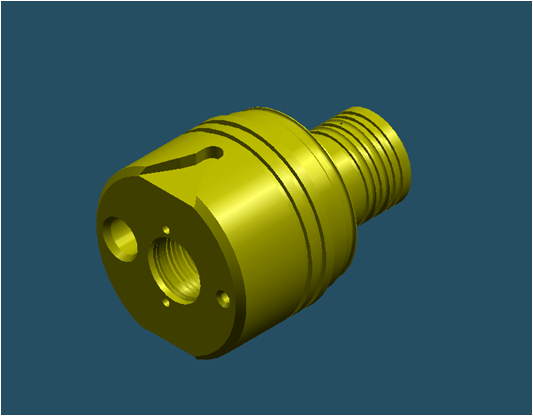

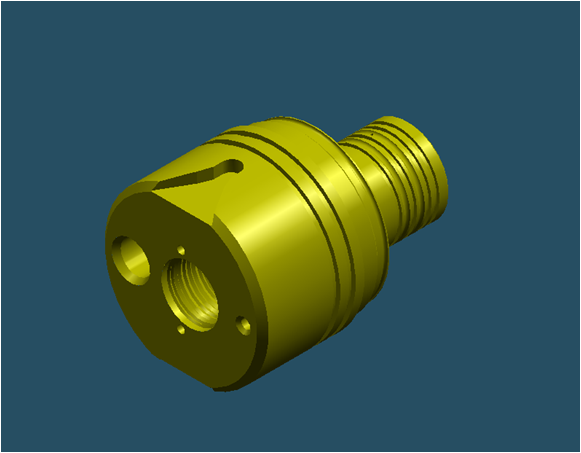

6.Direct cable crossing structure

Easy installation: Stripping the three foot long cable housing on the cable that needs to install the seal. There is no need to strip off all cable housings.

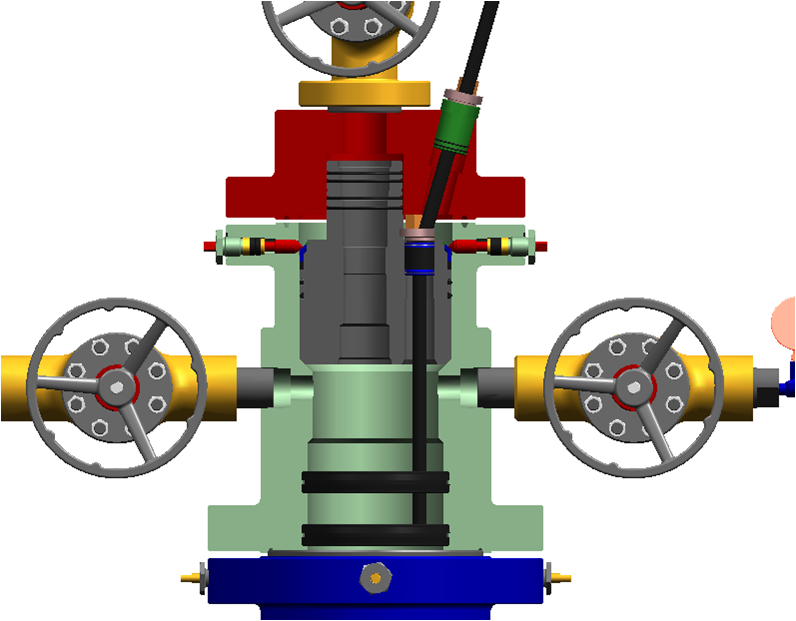

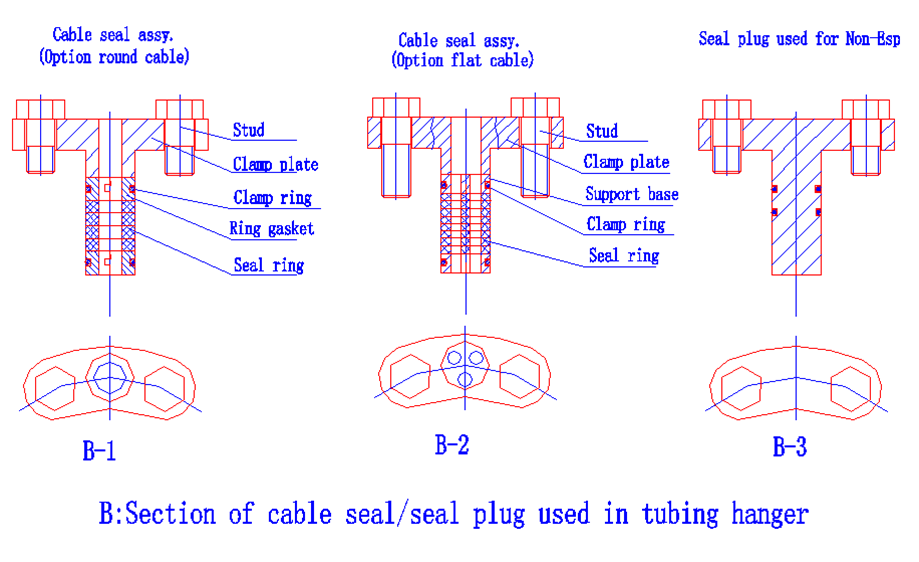

7.Tubing hanger structure

Extension neck type tubing hanger has several optional holes for SCSSV control lines, chemical reagent injection lines, and data cable control lines.Extension neck type tubing has lifting thread and BPV thread.

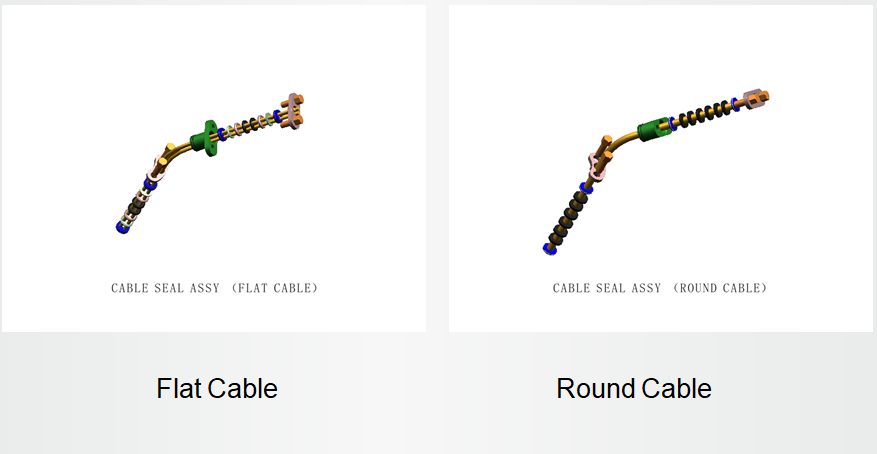

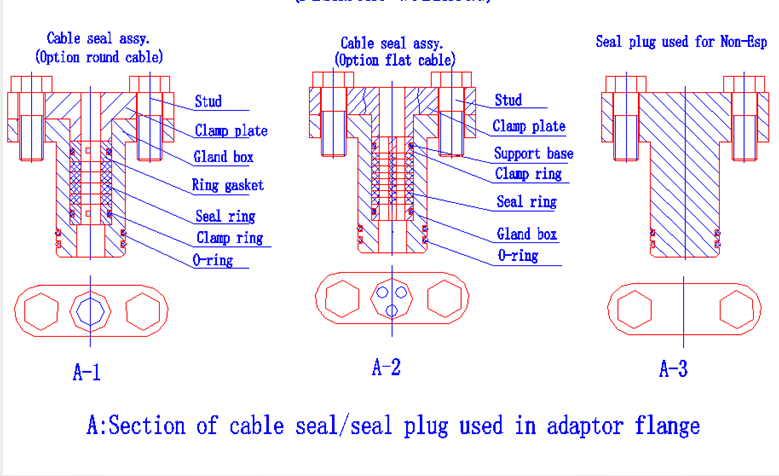

8.Tubing hanger and transfer flange cable seal

9.Cable seal diagram (flat cable)

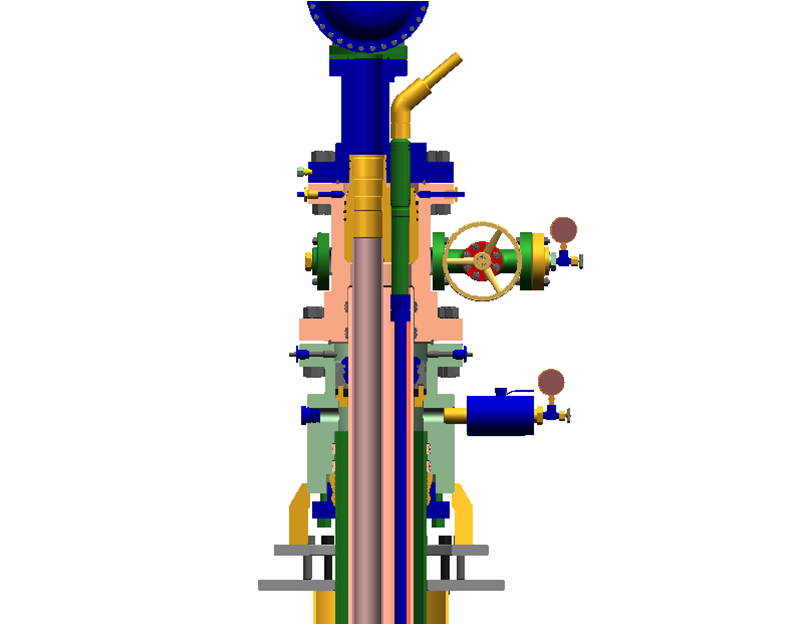

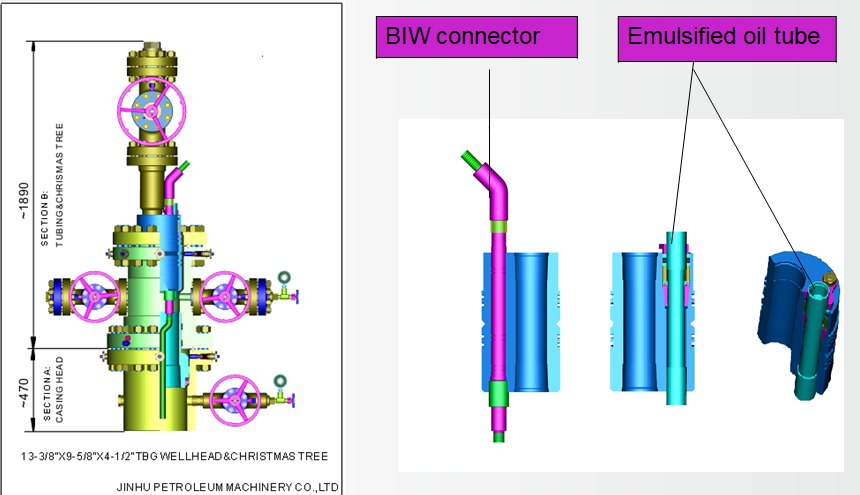

10.Electric pump wellhead equipment with BIW connector crossing

Features:3000psi~10000psi.Complex Installation.Reliable Seal.BIW connector crossing.High Cost.

11.Electric pump wellhead equipment with BIW connector crossing

Complex installation: Connect cables and BIW upper and lower connector. Cut the cables and connect them sequentially: Cable and lower connector; upper connector and cable.The BIW connection of the tubing hanger and the conversion joint can be tested for 10000psi.The connection between the connector and the BIW connector is convenient.

12.Bohai QHD32-6 project

13.Sultan 37 district project

Working pressure:5000PSI. Cable type: BIW connector 5KV 160A

14.Venezuela emulsified oil project

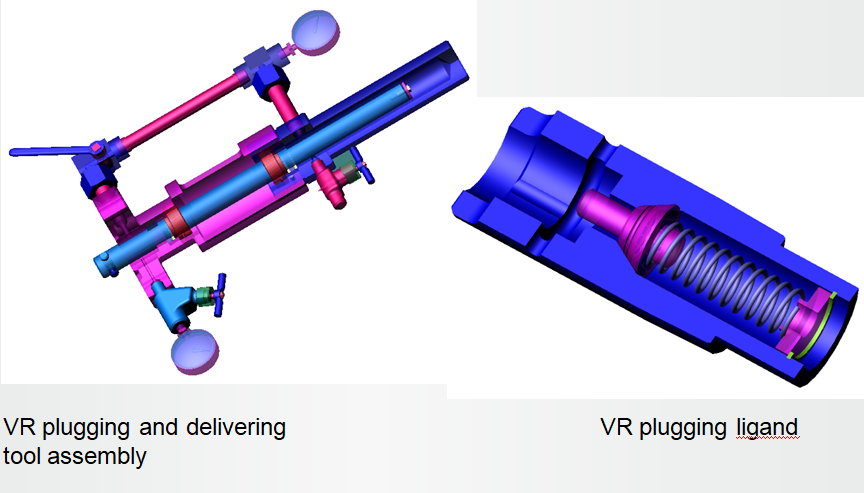

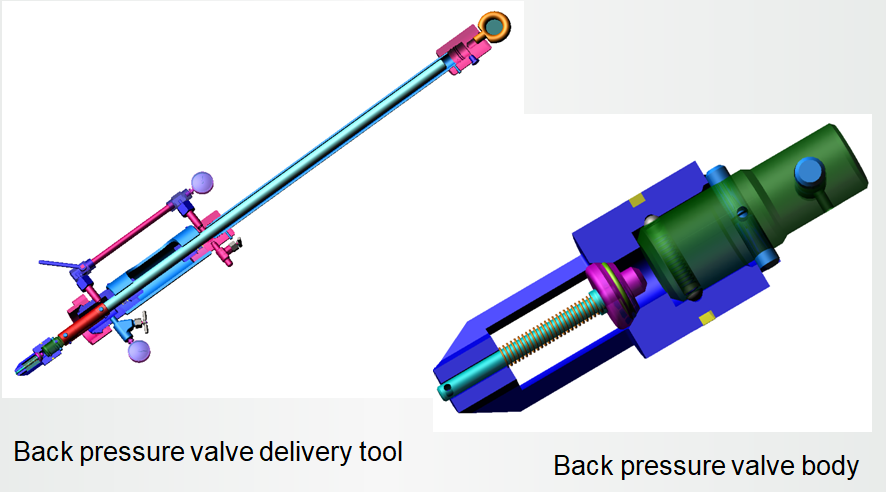

15.LF13-2 Wellhead project supporting tools(the back pressure valve feeding and removal tool)

16.LF13-2Wellhead project supporting tools(VR plugging in and taking out tools